Sistemas de Proceso

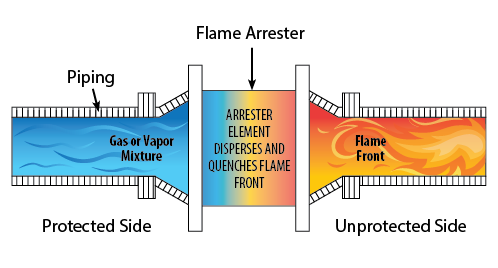

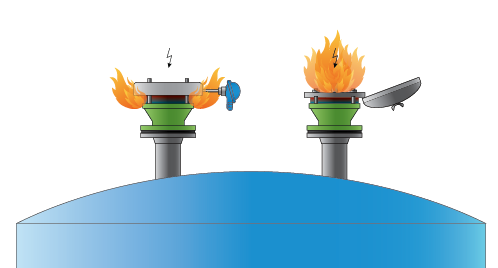

BS&B flame arresters prevent flame and explosion from entering pipes and vessels within industrial settings. Flame arresters allow the flow of gas and vapor through pipes and vessels. However, if a flammable reaction occurs, the explosive fireball and flames are extinguished before exiting or entering machines, equipment and plant processes.

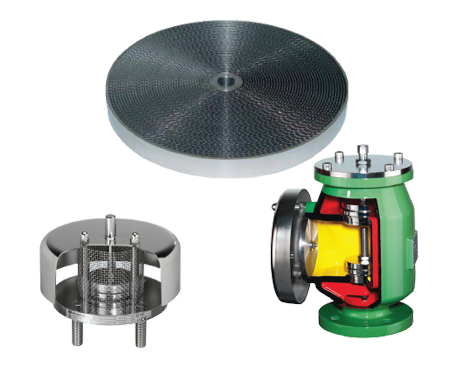

BS&B FlameSaf Flame Arrester products use the technical principle of a ‘quenching gap’. Precision coiled arrester elements are manufactured to allow normal flow to occur and to present a barrier to flame propagation. The quenching gap selected for the combustion condition of each application is too small for flame to pass and burning is ‘arrested’. Precision coiled arrester elements offer superior safety as compared to mesh type arresters which offer less stability of quenching gap.

The BS&B FlameSaf product line includes arrester technology suited to safe management of deflagration and detonation risks in piping systems and equipment. End-of-line and inline devices are available along with P/V vents that offer integral arresters.

- Product Details

- Applications

- Download

Features

Functions of Flame Arrester

BS&B is a certified manufacturer of flame arresters, detonation arresters and pressure / vacuum vents both with and without flame arrester function. Our flame arresters and Breather Vents (pressure/vacuum vents, P/V vents) incorporate impressive design and performance features that include compact and light weight construction, with low pressure loss in flowing conditions. The easy to assemble design enables quick installation of replacement parts when required.

BS&B Flame Arresters are used to protect systems for generating, storing and transporting gases and liquids of every hazard category against dangers of deflagration, detonation and stabilized burning.

Specifications

Certification

All products have been certified through an independent certification body as per the EC Directive 94/9/EC and awarded the CE mark of conformity. Our state-of-the-art flow and dimensional measurement techniques ensure the user receives high quality safety devices compliant with Industry Standards. Product performance features are controlled according to EN 10204 and in line with customer special requirements. The BS&B FlameSaf quality assurance system is monitored by Det Norske Veritas (DNV), who issue certification according to ISO 9001 to BS&B.

BS&B FLAME ARRESTER APPLICATIONS

Flame arresters are categorized into the following explosive combustion process including:

- In-line Deflagration Flame Arresters

- In-line Detonation Flame Arresters

- End-of-line Deflagration Arresters

- Endurance Burning Flame Arresters

- Breather Vents

- Safety Components

In-line Flame Arrester

Deflagration Flame Arrester,

end-of-line

Functions of Flame Arrester

Protects systems for generating, storing, and transporting gases and liquids of every hazard category against dangers such as deflagration, detonation and stabilized burning.

Deflagration

A deflagration is an explosive combustion process in which the flames propagate at subsonic velocity. There are end-of-line and in-line deflagration flame arresters

Detonation

A detonation is an explosion propagating at supersonic velocity characterized by a shock wave. The flame arresting capability and mechanical strength of an in-line detonation flame arrester is much greater than an in-line deflagration flame arrester. Devices designed for detonation conditions will provide deflagration protection as well.

Stabilized Burning

Stablized burning is the steady burning of a flame at or on a flame arrester element.